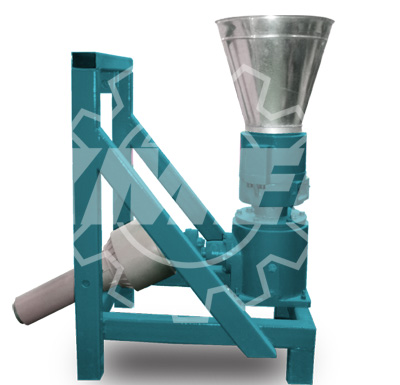

small poultry feed machinery

In recent years, poultry breeding industry develops fast. Traditional poultry feed cannot meet the requirement now. With the help of poultry feed machinery, you can easily make your own poultry feed pellets at home to accelerate the fast growth of poultry. The feed pellet machine can turn original raw materials into small pellets. The feed pellet mill machine made from KMEC adopts flat die design and has compact structure. So poultry feed mill with flat die is appropriate for home use to make feed pellets. There are two rollers and a die inside the small pellet press. When the machine runs, rollers and die will run to generate great force and high temperature. The great force will compress raw materials into die holes to form small pellets. With a knife cutting them to uniform size, cattle feed pellets are finished. Why do you choose poultry feed machinery from KMEC? Because our machine is equipped with various driven motor to be optional to meet your diverse needs.

Motor-driven type (Model B)

| Type | Power(kw) | Output(kg/h) | Weight(kg) | Package Size(mm) |

|---|---|---|---|---|

| ZLSP 120B | Three phase 3 | 60-100 | 80-100 | 750*320*680 |

| ZLSP 150B | Three phase 4 | 90-120 | 95/110 | 800*450*700 |

| ZLSP 200B | Three phase 7.5 | 200-300 | 200/230 | 1650*820*1200 |

| ZLSP 230B | Three phase 11 | 300-400 | 290/320 | 1050*480*930 |

| ZLSP 260B | Three phase 15 | 400-600 | 320/360 | 1180*540*1000 |

| ZLSP 300B | Three phase 22 | 600-800 | 350/380 | 1240*540*950 |

Motor-driven type(Model C)

Technical Parameters:

| Type | Power(kw) | Output(kg/h) | Weight(kg) | Package Size(mm) |

|---|---|---|---|---|

| ZLSP 150C | Three phase 4 | 90-120 | 105/125 | 1000*480*780 |

| ZLSP 200C | Three phase 7.5 | 200-300 | 210/230 | 1050*550*830 |

| ZLSP 230C | Three phase 11 | 300-400 | 290/320 | 1200*560*950 |

| ZLSP 260C | Three phase 15 | 400-600 | 340/370 | 1240*580*1000 |

| ZLSP 300C | Three phase 22 | 600-800 | 425/465 | 1300*620*1100 |

Diesel-engine Driven Type (Model A)

| Type | Power(Hp) | Output(kg/h) | Weight(kg) | Package Size(mm) |

|---|---|---|---|---|

| ZLSP 120A | 8 | 60-100 | 120/140 | 900*500*730 |

| ZLSP 150A | 8 | 90-120 | 180/220 | 1000*500*750 |

| ZLSP 200A | 15 | 200-300 | 210/240 | 1460*750*900 |

| ZLSP 230A | 22 | 300-400 | 280/310 | 1560*850*1000 |

| ZLSP 260A | 30 | 400-600 | 330/360 | 1200*500*1070 |

| ZLSP 300A | 55 | 600-800 | 410/450 | 1220*600*1000 |

Technical Parameters:

| Type | Power(Hp) | Output(kg/h) | Weight(kg) | Package size(mm) |

|---|---|---|---|---|

| ZLSP 120Q | 7.5 | 60-100 | 120/140 | 900*500*730 |

| ZLSP 150Q | 10 | 90-120 | 180/220 | 1000*500*750 |

Technical Parameters:

| Type | Power(Hp) | Output(kg/h) | Weight(kg) | Package size(mm) |

|---|---|---|---|---|

| ZLSP 150P | ≥8 | 90-120 | 105/125 | 900*540*1020 |

| ZLSP 200P | ≥15 | 200-300 | 210/230 | 1000*540*1020 |

| ZLSP 230P | ≥22 | 300-400 | 290/320 | 1000*540*1020 |

| ZLSP 260P | ≥30 | 400-600 | 340/370 | 1050*540*900 |

| ZLSP 300P | ≥55 | 600-800 | 425/465 | 1100*540*1000 |

Why feed pellets made by poultry feed machinery is superior to traditional feed?

► With this machine, you can mix ingredients that the growth of poultry needs together according to your recipe. When poultry are taking food, they can no longer piddling certain feed or ingredient. This promises the balance of poultry absorbing nutrition.

► As we mentioned above, during pelletizing process, high temperature will be generated. This will make materials ferment and kill some harmful bacteria so that palatability of feed is improved while some disease can be avoid.